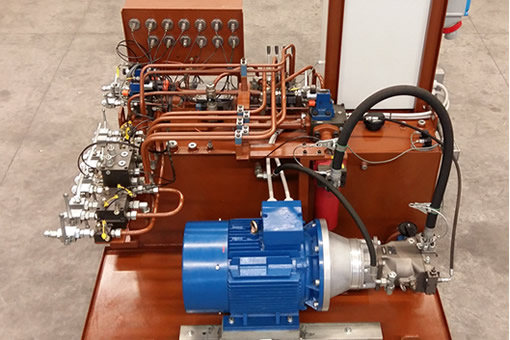

Manufacture of hydraulic, pneumatic and lubrication systems installed on the machine, complete "turnkey" systems, fluid distribution systems, installations all over the world.

Interconnecting piping plants, including engineering and material supply.

Transfers with our equipped vans up to 1000 km away, shipping equipment in containers for intercontinental transfers.

Revamping service on existing plants, disassembly, cleaning, overhaul of pumps, replacement of components, repainting, reassembly and final testing;

Refurbishment of existing pipes, removal of leaks.

Revamping of hydraulic power plants, valve banks and systems with the aim of making them more efficient in order to extend their life cycle within the production process.

System Fluid is able to guarantee its Customers renovation of existing systems to restore their efficiency and reliability.

Maintenance contracts for the service of hydraulic systems, updating of hydraulic diagrams, drafting of spare parts lists and check-lists;

Recharge of hydraulic accumulators with nitrogen, also directly at the Customer premises for pressures up to 400 bars;

Replacement of hoses complete with holding system according to current standards;

Replacement of filter elements.

System Fluid srl performs the pressure check and nitrogen recharge of the hydropneumatic accumulators that, by exploiting the compressibility of the inert gas, allow the storage of fluids under pressure, with the aid of a multiplier (booster), refills are made up to a pressure of 400 bars.

Internal cleaning of oil-hydraulic tanks, filtration and dehydration of oil in operation, replacement of oil charges;

Flushing of systems in turbulent motion;

Internal mechanical cleaning of pipes with ALKA system

Prefabrication according to your drawing or after our tubing and piping survey, using the most innumerable connection technologies;

Shaping and calendaring of tubing and piping, X-ray radiographs of welds, pressure tests, pickling, electro-galvanic galvanizing, painting according to specific cycle.

Shaping of pipes up to ø 4” schedule 80 (114.3 x 8.56 mm) or ø 3” schedule XXS (88.9 x 15.24 mm)

Calendaring pipes up to ø 2” schedule 40 (60.3 x 3.91 mm)

Mechanical assembly and metal carpentry.

Rental of oil-hydraulic power plants, flushing plants, oil dehydration units, TRIPLE R microfiltration units.

Power plants for tests and functional tests up to 420 bars

High-pressure unit up to 1500 bars

TRIPLE R filtration units with different flow rates for oil purification, filter elements of absolute 2 µm